Day 1

Driver A:

Day 1

Driver B:

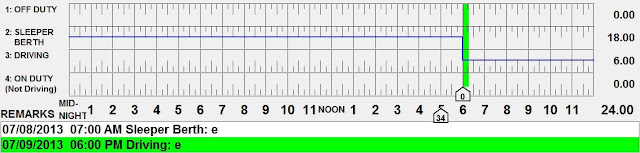

Day 2

Driver A:

Day 2

Driver B:

Day 3

Driver A:

Day 3

Driver B:

Day 4

Driver A:

Day 4

Driver B:

Day 5

Driver A:

Day 5

Driver B:

Day 6

Driver A:

Day 6

Driver B:

Day 7

Driver A:

Day 7

Driver B:

Day 8

Driver A:

Day 8

Driver B:

This example is missing a few elements that most drivers run into such as: Fuel, Meal Breaks, Load Inspections, Pre, Mid, and Post-Trip Inspections. Every truck would perform a load check within the first 50 miles, and then flatbeds would perform load checks every additional 150 miles, 3 hours, or duty status change (whichever comes first)

This is a 8 on, 8 off, 3 on, 3 off, combination, but an 8 on, 3 off, 3 on, 8 off configuration would work as well.

Most trucks don't run around the clock like this. This team hit their 70 hours on day 6 at 9 PM causing the truck to stop until day 7 at 3 AM. It could move 4 more hours until it had to stay stopped until Day 8 at 7 AM when the team could resume operations again.

Just as soon as you finish reading this, the HOS will change again. Who knows when the FMCSA will stop fiddling with these regulations. Your guess is as good as mine.